Masking

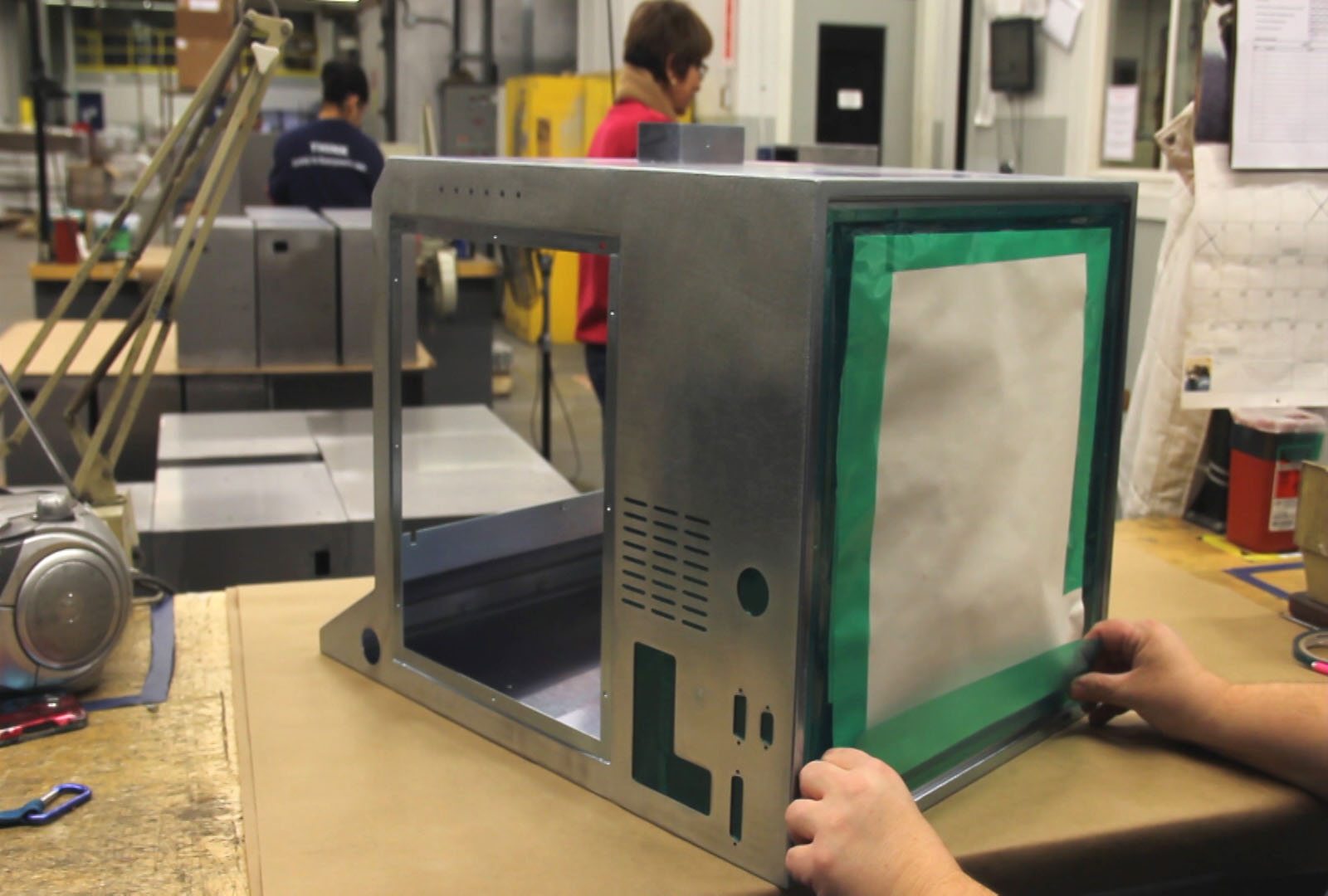

Westside Finishing provides detailed and accurate masking using a wide variety of materials, according to your specifications.

We utilize many different materials in our masking department in order to achieve the desired result.

- We have special high temperature tapes and dots to protect specified areas from powder coating. In addition to the factory cut materials we can utilize our Roland GX-24 computerized plotter to make specialty masks to fit complex parts.

- We use silicone plugs and caps to prevent powder from coating any threaded holes, inserts or studs.

- We also have the capability to utilize Chomerics Cho-Mask tape. A specialty tape that can be a cheaper and faster alternative to plating in some cases.

There is no job too complicated for our skilled maskers to accomplish. When our customers supply a blue print we can review and mask the parts to extremely tight tolerances.

Our masking department is headed by an individual who has been with our Western MA company for over 15 years. The department supervisor and the individual who will be processing the job get together to review your blue prints, drawings and specifications in order to ensure that your product is masked and prepped per your specifications.

After the masking of a job is complete a final inspection is performed prior to the next process. This is done to ensure that there will be no mistakes in the masking before the powder coating is applied and cured.